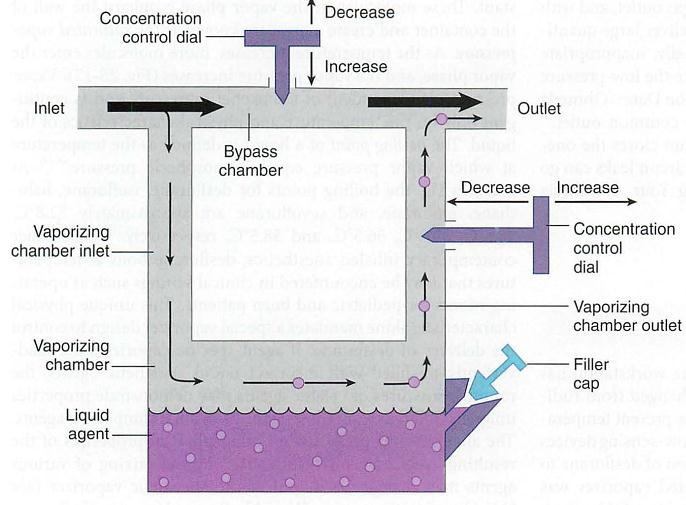

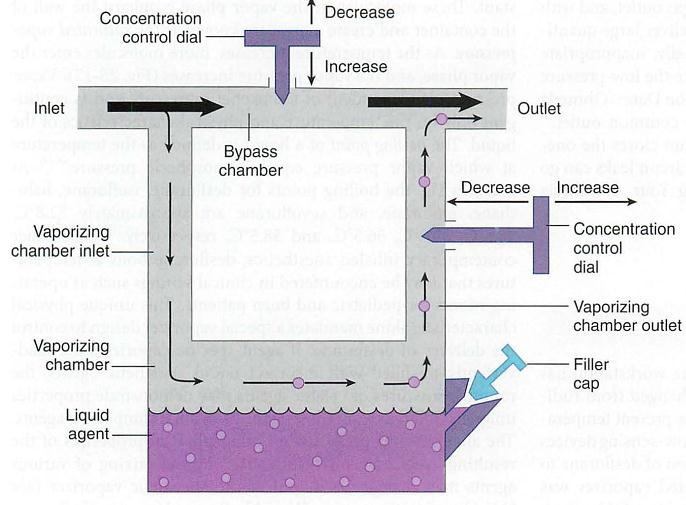

A vaporizer is an instrument designed to change a liquid anesthetic agent into its vapor and add a controlled amount of this vapor to the fresh gas flow (Figure 2.6 and 2.7). Volatile anesthetics are liquids at room temperature and atmospheric pressure. Vaporization, which is the conversion of a liquid to a vapor, takes place in a closed container, referred to as a vaporizer. The vapor concentration resulting from vaporization of a volatile liquid anesthetic must be delivered to the patient with the same accuracy and predictability as other gases (oxygen, nitrous oxide).

Commonly, two to three anesthetic-specific vaporizers are present on the anesthesia machine. A safety interlock mechanism ensures that only one vaporizer at a time can be turned on. Turning on a vaporizer requires depression of a release button on the concentration dial, followed by counterclockwise rotation of the dial. This prevents accidental movement of the dial from the off to the on position. The location of the filler port on the lower portion of the vaporizer minimizes the likelihood of overfilling of the vaporizing chamber (>125 mL) with liquid anesthetic.

Vaporizers are often constructed of metals with high thermal conductivity (copper, bronze) to further minimize heat loss. As a result, vaporizer output is nearly linear between 200C and 350C. Designation of vaporizers as agent specific and out of circuit emphasizes that these devices are calibrated to accommodate a single volatile anesthetic and are isolated from the anesthetic breathing system.

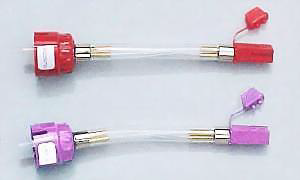

Figure 2:8 Vaporizer Fillers Filling the vaporizer using the key filler system (Figure 2.8 and 2.9)

|

Figure 2:9 External feature of vaprizer and anesthetic volatile agents |

Hazards of vaporizer